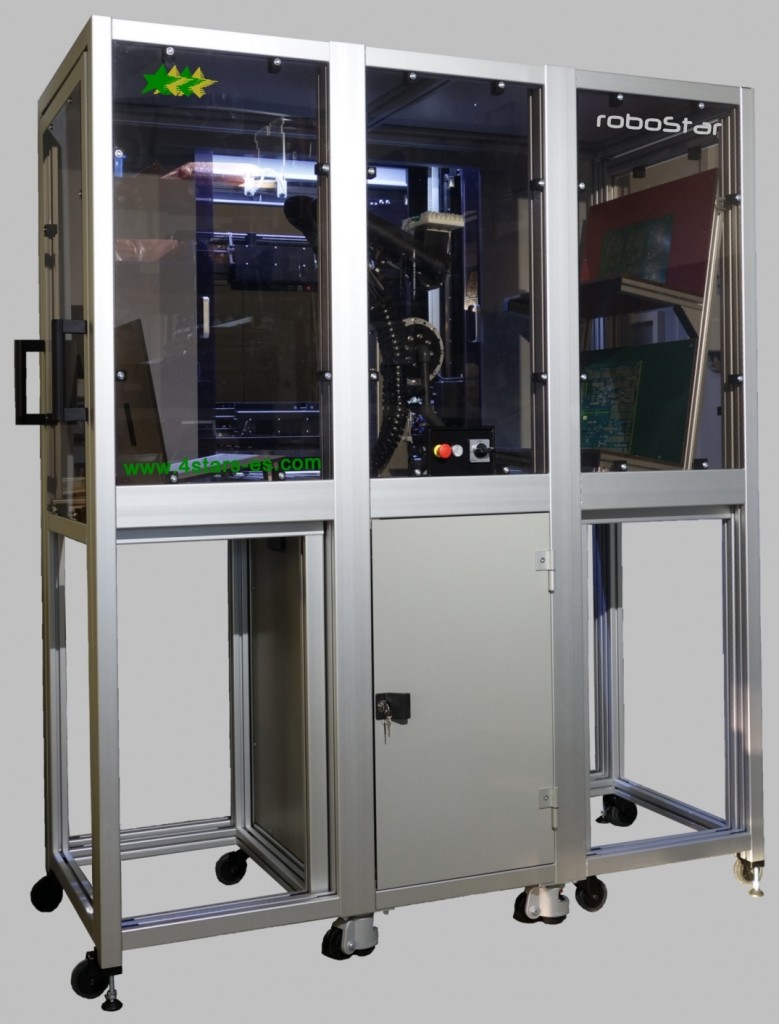

roboStar

Automation for Flying Probe Testers (roboStar)

roboStar Automation is a machine for loading and unloading PCBs into/from Flying Probe Testers.

roboStar Automation is perfectly driven and controlled by the FourStars-ES ProbeStar Software.

The main functions of roboStar are:

- Load PCB from Input-Stack into FPT.

- Unload PCB from FPT to Good- or Bad-Stack.

- Switch Jobs and PCB Sizes during operation without operator interaction

- Optional Error Tag allocation

roboStar Automation

The unit contains:

- 4 axis robot with vacuum gripper to handle PCBs

- Removable Input-Trolley with PCB Input-Stack ( for PCBs to be tested)

- Removable Output-Trolley with PCB Good-Stack and PCB Bad-Stack (for tested PCBs)

- Power Supplies, Vacuum Generator

- High performance SoC for real time robot control and PCB management

- Gigabit-Ethernet-Interface to the controlling FPT-PC

Mechanical Solution:

- State of the Art components

- Assembled and tested at FourStarsES

Specification:

- PCB physical Parameters:

- Minimum Size: 115 mm x 115 mm x 1.0 mm (w x h x t)

- Maximum Size: 460 mm x 325 mm x 2,5 mm (w x h x t)

- Maximum Weigth: 1 kg

- Stack Size:

- 220 mm

- 220 PCBs @1.0 mm thickness

- 137 PCBs @ 1.6 mm thickness

- Power:

- Voltage: 230V/110V, 50/60 Hz

- Maximum Current: 10A/16A

- Maximum Consumption: 2kW

- Air:

- Pressure: 5 bar

- Maximum Consumption: 395l/min